Why Your Maintenance Projects Never Get Finished (And How to Fix It)

Table of Contents

You've seen it happen.

A maintenance project starts with good intentions. Equipment gets disassembled. Parts are ordered. The work area is cordoned off. And then... silence.

Days pass. Then weeks. Maybe even months. The project sits there, incomplete, creating safety hazards, operational problems, and mounting frustration for everyone in your building.

You check in with your maintenance person or contractor. They give you excuses:

- • "Waiting on parts"

- • "Had to handle some emergencies"

- • "It's more complicated than I thought."

- • "I'll get to it next week."

But next week comes and goes. The project remains unfinished. And now you have a new problem: you're stuck with a half-completed repair that's often worse than the original issue.

At Managed Services, Inc. (MSI), we've been called in to complete dozens of abandoned maintenance projects across the Twin Cities metro area. It's one of the most common—and most frustrating—facility maintenance problems that businesses face.

In this article, we'll explore why maintenance projects get abandoned, what this problem costs your business, and how to ensure projects actually get completed the first time.

Why Maintenance Projects Get Started But Never Finish

Understanding why projects get abandoned is the first step to preventing it. Let's look at the most common causes.

Cause #1: Insufficient Technical Knowledge

This is the most frequent culprit. Your maintenance person or contractor knew enough to start the project, but didn't have the expertise to complete it.

Here's how it typically unfolds:

Initial assessment seems simple: "It's just replacing a component. Should be straightforward."

Disassembly reveals complexity: Once equipment is taken apart, unexpected complications appear. The replacement part doesn't quite fit. There are additional damaged components. The system is configured differently than expected.

Knowledge gap becomes apparent: The technician realizes they don't actually know how to solve the problem they've uncovered. Rather than immediately admitting this and calling for help, they:

- Try to figure it out themselves (unsuccessfully)

- Move on to other tasks "temporarily"

- Hope the problem will somehow become clearer later

- Eventually, avoid the project altogether

We've taken over projects where the technician:

- Removed HVAC components, but couldn't figure out the correct reinstallation sequence

- Started electrical work, but couldn't properly identify and reconnect wiring

- Disassembled plumbing systems but lacked the tools or knowledge to complete the repair

- Began equipment installations without understanding the full scope of requirements

Cause #2: Missing Tools, Equipment, or Parts

Even skilled technicians can't complete work without the right resources.

Specialized tools aren't available: Many facility maintenance tasks require specific tools. If your maintenance person doesn't have them (and doesn't want to admit it), projects stall.

Parts availability issues: The replacement part ordered from the supplier is backordered. Or the wrong part was ordered. Or the part that arrived doesn't match the specifications. Without a strong supply chain relationship and technical knowledge to specify parts correctly, projects can stall for weeks.

Supply chain problems: Even when the right part is ordered, delivery delays can extend timelines dramatically. If there's no system for tracking these delays and proactively communicating with stakeholders, projects sit in limbo.

We've encountered situations where:

- Equipment has been disassembled for weeks, waiting on a backordered part

- The wrong parts were ordered multiple times because the technician couldn't identify the correct specifications

- Work stopped because the technician didn't have (and didn't want to purchase) a specialized tool needed for completion

Cause #3: Poor Project Management and Tracking

When there's no system for managing and tracking maintenance projects, work falls through the cracks.

No accountability structure: If your maintenance person is essentially self-managed, who's ensuring projects get completed? Whose tracking status? Who's holding them accountable for follow-through?

Lack of prioritization: Without clear priorities, everything seems equally important (or equally unimportant). Projects get started based on mood or convenience rather than actual urgency, and completion isn't tracked systematically.

No communication protocols: When projects encounter obstacles, is there a clear communication path? Does your maintenance person know they should immediately inform you of delays rather than just hoping to figure it out eventually?

Missing documentation: Without proper documentation of what's been done, what needs to be done, and what's required for completion, projects lose momentum. When someone picks up an abandoned project weeks later, they have to start over, trying to understand what was done and what remains.

Cause #4: Competing Priorities and Distractions

Even when someone has the skills and resources to complete a project, competing demands can derail progress.

Emergency repairs take precedence: A burst pipe or broken HVAC system rightfully becomes the immediate priority. But once the emergency is handled, the original project may never get resumed.

Other responsibilities interfere: If your maintenance person has duties beyond facility maintenance (which is common in smaller organizations), those other responsibilities may constantly interrupt project work.

Lack of dedicated project time: Starting a project requires focused time. If your maintenance person is constantly being pulled in different directions, projects never get the concentrated attention needed for completion.

Out of sight, out of mind: Once a project is "temporarily" set aside, it's easy for it to be forgotten. Especially if the work area isn't visible or the incomplete work doesn't immediately impact operations, it can stay abandoned indefinitely.

Cause #5: The "I'll Figure It Out Later" Mentality

This is perhaps the most insidious cause because it's harder to identify.

Some maintenance workers encounter problems and think, "I'll work on this when I have more time" or "I'll figure this out later" without recognizing that "later" may never come.

This happens when:

- Pride prevents admitting the project is beyond their skill level

- Fear of consequences stops them from reporting problems early

- Optimism bias makes them believe they'll somehow figure it out eventually

- Lack of professionalism means they don't take ownership of completion

The Real Cost of Unfinished Maintenance Projects

Abandoned projects aren't just annoying—they're expensive and dangerous. Let's look at the true impact.

Safety Hazards and Liability

Exposed electrical work: Open electrical panels or disconnected wiring create shock hazards and fire risks. Every day that electrical work remains unfinished is a day of liability exposure.

Open plumbing: Removing drain covers, exposed pipes, or partially dismantled plumbing can cause slips, falls, or water damage.

Structural hazards: Removing ceiling tiles, wall panels, or floor coverings creates trip hazards and fall risks.

Non-functional safety systems: If the abandoned project involves fire suppression, emergency lighting, or security systems, you may be non-compliant with codes and regulations—a serious legal problem.

We've been called to sites where OSHA would have had a field day with the safety violations created by abandoned projects.

Equipment Failures and System Breakdowns

Partial repairs create new problems: An HVAC system partially disassembled for maintenance can't function at all. A half-completed plumbing repair may make leaks worse. Incomplete electrical work can damage equipment.

Environmental damage: Equipment left disassembled and exposed to weather or building conditions can corrode, degrade, or become damaged, turning a simple repair into a replacement project.

Cascading failures: One incomplete repair can stress other systems. An HVAC system that's not working properly makes other equipment work harder. A plumbing issue that's partially addressed can cause water damage to other systems.

Operational Disruptions

Work areas blocked off: Space that should be productive remains cordoned off and unusable while waiting for project completion.

Equipment unavailable: Systems that should be operational remain down, impacting productivity and comfort.

Workarounds become permanent: People develop workarounds for missing functionality, leading to inefficiency and potential safety risks.

Employee or tenant complaints: Nothing damages morale faster than seeing the same unfinished project week after week with no resolution. It sends a message that management doesn't care or can't get things done.

Financial Costs Multiply

Paying twice (or three times): You paid for the initial work that didn't get completed. Now you'll pay someone else to complete it. Plus, you may need to pay to fix damage caused by the incomplete work. Some projects we've taken over required completely start over completely because the initial work was done incorrectly.

Emergency service premiums: When a half-completed project creates an urgent problem, you pay emergency rates to fix it—often 2-3 times higher than regular service rates.

Lost productivity: Employees or tenants working around incomplete repairs waste time and reduce efficiency.

Damaged equipment: Equipment left in a partially states of disassembly can sustain damage that creates additional repair costs.

Energy waste: Systems running inefficiently due to incomplete maintenance consume more energy while providing poor performance.

Real Examples: The Cost of Incomplete Work

Let me share some actual cases we've encountered.

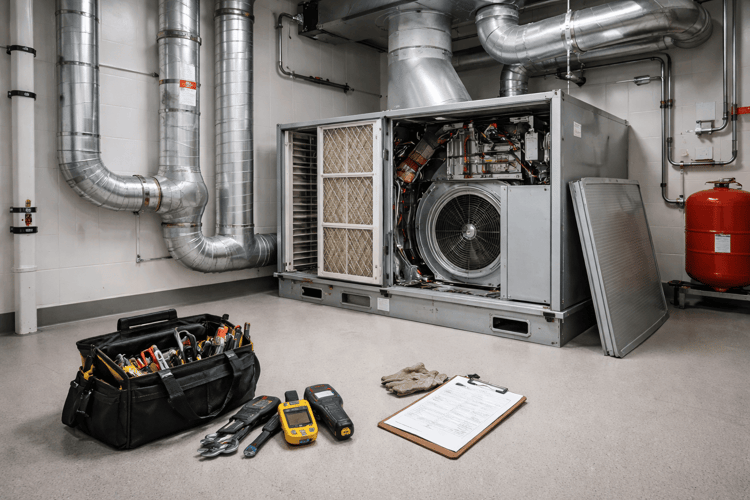

The HVAC System That Sat Disassembled for Six Weeks

We received a call from a commercial office building in distress. Their maintenance contractor had started routine HVAC maintenance six weeks earlier. During the work, he discovered some components needed replacement. He ordered parts, disassembled additional components for access, and then... disappeared.

The contractor stopped returning calls. The parts arrived but sat in boxes. And the building's HVAC system couldn't operate properly with critical components removed and sitting on the mechanical room floor.

This was in July. In Minnesota, that means the building was uncomfortably warm. Tenants were complaining. Productivity was suffering. And the building owner was desperate.

When our team arrived:

- We found critical HVAC components incorrectly disassembled

- Some parts had been ordered, others were wrong

- Documentation of what was done was nonexistent

- The mechanical room was a mess of parts and tools

Our technicians had to essentially reverse-engineer what the original contractor had done, identify what was still needed, order the correct parts, and complete the work properly.

Total time the system was down: 6 weeks

Cost to the building owner: Original contractor's partial payment + our fees to complete + premium for urgency + tenant complaints and possible lease violations + energy waste from the impaired system

This project should have taken two days with proper planning and follow-through.

The Plumbing Project That Created a Safety Hazard

A manufacturing facility had a floor drain issue in its production area. Their in-house maintenance person started the repair by removing the drain grate and some of the piping.

Then he went to lunch and never returned. Not that day. Not the next day. Not ever. He ghosted the job completely.

The facility was left with an open hole in the floor in an active production area—a significant trip and fall hazard. Workers had to navigate around it. The company set up temporary barriers, but it remained dangerous.

After several days of trying to reach their maintenance person, they gave up and called us for emergency help.

The problems we found:

- The drain grate and some pipes were removed but work hadn't progressed beyond demolition

- No clear plan for what the repair actually required

- No parts on hand to complete the work

- Significant safety liability from the open hole

We had to:

- Immediately make the area safe

- Diagnose the actual plumbing issue

- Source proper materials

- Complete the repair correctly

Total time the area was hazardous: 4 days

Cost: Lost productivity + safety risk + emergency service fees + the wages already paid to the disappeared maintenance person

The Electrical Project That Made Things Worse

An office building needed some outdated lighting fixtures replaced in their main hallway. Their maintenance person seemed confident he could handle it.

He removed the old fixtures. That part went fine. Then he tried to install the new ones.

Three weeks later, the hallway was still partially dark. Some new fixtures were installed, but not working. Others weren't installed at all. Wiring was left exposed in some locations. The project was a disaster.

When management finally asked what was happening, they got vague answers about "electrical issues" and "waiting on parts." Eventually, they admitted defeat and called in a professional electrician (us).

What we discovered:

- The new fixtures were wired incorrectly (creating a fire hazard)

- Some circuits were damaged during the attempted installation

- The original fixtures that were removed couldn't be reinstalled even if they wanted to go back

- Building occupants had been working under partial darkness and a fire hazard for three weeks

Our electrician corrected the dangerous wiring, repaired the damaged circuits, and properly installed all the new fixtures.

Total time with safety hazards and poor lighting: 3 weeks

Cost: Wages paid to the maintenance person + materials wasted + professional electrician fees to fix everything + three weeks of employee complaints about the dark hallway + liability exposure from fire hazards

The project should have been completed in one day by a qualified electrician.

How Professional Facility Maintenance Prevents Abandoned Projects

The pattern in all these examples is clear: projects get abandoned when there's no accountability, inadequate skill, poor communication, or lack of project management.

Professional facility maintenance companies solve these problems through structured processes and systems.

Comprehensive Project Management

At MSI, every work order is tracked from initiation to completion:

Clear assignment: Projects are assigned to technicians qualified for that specific work.

Progress tracking: Management monitors project status throughout the work cycle.

Obstacle identification: When challenges arise, they're identified and addressed immediately rather than becoming reasons for abandonment.

Communication protocols: Clients are updated on project status, especially when unexpected complications or delays occur.

Completion verification: Work is inspected and verified complete before closing the work order.

Nothing slips through the cracks because there's a system designed to prevent it.

Right Technician for the Job

Unlike hoping one general maintenance person can handle everything, professional services match the project to the appropriate specialist:

HVAC work goes to HVAC technicians

Electrical projects go to licensed electricians

Plumbing repairs go to plumbing specialists

General maintenance goes to general maintenance professionals

This means:

- Projects are completed by people who actually know how to do the work

- The learning curve doesn't happen on your project

- Complications can be handled because the technician has the expertise

Proper Tools and Resources

Professional facility maintenance companies arrive with:

- The right tools for any job

- Access to proper equipment

- Established supplier relationships for quick parts procurement

- Backup options when parts are delayed

Projects don't stall because we don't have the specialized tools or can't source the parts needed.

Built-In Accountability

When a project is assigned to a professional service:

- The company's reputation is on the line

- Management oversight ensures follow-through

- There are consequences for not completing work

- Customer satisfaction is measured and tracked

Compare this to an individual maintenance person who may feel little accountability for completion—especially if they know finding their replacement would be difficult.

Team Backup and Continuity

If the technician working on a project is unavailable (sick, emergency elsewhere, etc.), the project doesn't stop. Another qualified technician can step in because:

- Work is documented in the system

- Other technicians can access project details

- Team collaboration is standard practice

This is impossible when you rely on a single in-house maintenance person.

What This Looks Like for Your Business

When you partner with MSI for facility maintenance, here's what project completion looks like:

Day 1: You submit a work order for a needed repair or project.

Day 1-2: We schedule the appropriate technician and source any needed materials.

Project Day: The technician arrives with proper tools, completes the work efficiently, and documents what was done.

Follow-up: We will verify with you that the work meets your expectations.

Ongoing: If any issues arise from the work, we address them immediately at no additional charge (warranty coverage).

Compare this to:

- Hoping your maintenance person has time to look at it

- Wondering if they actually know how to do the work

- Waiting while they order parts (maybe the right ones, maybe not)

- Checking back repeatedly to see if progress is being made

- Dealing with the project being abandoned midway through

Making the Change: From Abandoned Projects to Reliable Completion

If you're tired of seeing maintenance projects languish incomplete, making the switch to professional facility maintenance is straightforward.

Step 1: Free Assessment

We evaluate your facility's maintenance needs and any currently incomplete projects.

Step 2: Immediate Action on Abandoned Projects

If you have projects sitting incomplete, we can prioritize getting those finished first, properly and safely.

Step 3: Ongoing Maintenance Plan

We develop a service plan that prevents the conditions that lead to abandoned projects: proper planning, the right technicians, adequate resources, and project tracking.

Step 4: Single Point of Contact

You have one number to call for all facility maintenance. One relationship. One company accountable for completion.

Step 5: Peace of Mind

You can stop worrying about whether projects will actually get finished. With our systems and accountability, they will.

The Bottom Line

Maintenance projects that never get finished are more than just frustrating—they're expensive, dangerous, and damaging to your business operations.

The root causes—inadequate skills, poor project management, lack of accountability, missing resources—aren't problems you can easily solve when relying on individual contractors or a single in-house maintenance person.

Professional facility maintenance companies eliminate these causes through structured systems, qualified technicians, proper resources, and accountability.

At MSI, we've completed hundreds of projects that others abandoned. We've seen every excuse, every complication, and every reason projects don't get finished. And we've developed the processes and systems to ensure our projects reach completion every time.

Your facility deserves maintenance work that actually gets completed—not projects that sit abandoned for weeks or months, creating problems instead of solving them.

Ready to End the Cycle of Incomplete Projects?

If you have maintenance projects sitting unfinished—or if you're tired of wondering whether new projects will actually reach completion—let's talk about how MSI can provide the reliable project completion your facility needs.

Contact Managed Services, Inc. today to schedule a free consultation about your facility maintenance needs and any incomplete projects we can help you finish.

Schedule a Free ConsultationWe serve businesses throughout the Twin Cities seven-county metro area with comprehensive facility maintenance services, including:

- HVAC mechanical services

- Electrical repairs and installations

- Plumbing services

- General maintenance and repairs

- Project management and completion

Let us show you what reliable project completion looks like—so you can stop dealing with abandoned projects and start enjoying maintenance work that actually gets finished.

Managed Services, Inc. (MSI) is a self-performing building maintenance service contractor serving the Twin Cities metro area. We specialize in completing maintenance projects properly, efficiently, and on time—no more abandoned work or half-finished repairs.